Case Study 1 : Data Cleansing

Client Background :

The client is one of the leading manufacturers and distributors in the Fertilizers and Industrial Chemicals sector having turn over around 10,000cr with 5 operating plants across India.

With a rapidly expanding product portfolio and a high volume of material transactions YOY, their Material Master Data had grown inconsistently over time to around 93,258 SKU’s with a inventory value of 125cr, leading to inefficiencies across supply chain, inventory, procurement, and compliance processes.

![]()

Challenges & Master Data Pain Areas :

The client faced critical data quality issues, including:

- Duplicate material codes across SAP

- SAP material group mismatches

- Inconsistent naming conventions and formats

- Spelling errors & unstructured material descriptions

- Missing technical attributes in material master such as OEM, MPN, Size, UoM, and drawing/tag details

- Difficulty in identifying obsolete and non-moving inventory

- Lack of a central tracking & data quality governance mechanism

- Operational delays in procurement and inaccurate stock forecasting

These challenges impacted business KPIs such as:

- Inventory & Inventory carrying cost

- Equipment Bill of materials (BOM) correctness

- Material searchability and reporting reliability

W2W Solution:

A Complete Data-Driven Master Data Quality Upliftment Approach

Material Master Data Cleansing & Governance Platform is deployed by W2W with following Core Transformation Framework

|

Project Stage |

Key Activities |

|

Data Cleansing |

Duplicate detection, phase-out spare identification (equipment/machine and technology), Conversion of OEM spares into standard spares |

|

Data Standardization |

Normalization of Category, OEM/MPN structuring, UoM, Size formats, Abbreviations, Tag numbers, Text Separator, etc. Design and implement string consistency based on customer requirements and MRO category standards |

|

Data Enrichment |

Technical Attribute such as OEM/MPN/Size/UoM etc., tags & drawing numbers, OEM equipment details. Implementation of attribute labels & value combination for long descriptions. |

|

Data Validation |

Technical Attributes verification from catalogues/drawings & through physical verification |

|

Inventory Reduction |

Identification and Classification of Non-Moving & Obsolete. Complete Identification of repetitive, and duplicate material codes (post-standardization and enrichment) |

|

MDM Support for Data Control, Data Governance & Sustainability |

MDM Tool Implementation Support including process design aligned with data standardization SOPs for new material code creation, integrated duplicate-check search functionality Continuous MDM tool support to govern and maintain data quality for new material code creation, sustained for over 6 years. |

|

S4 HANA Implementation Support |

SAP template-based data transformation, including mapping of material groups and sub-groups, material type, unit of measure (UoM), accounting data, and HSN codes, along with conversion of long material descriptions to meet template requirements. |

Results & Business Impact :

1. Material Master Data Complexity Reduction and Quality Improvements :

-

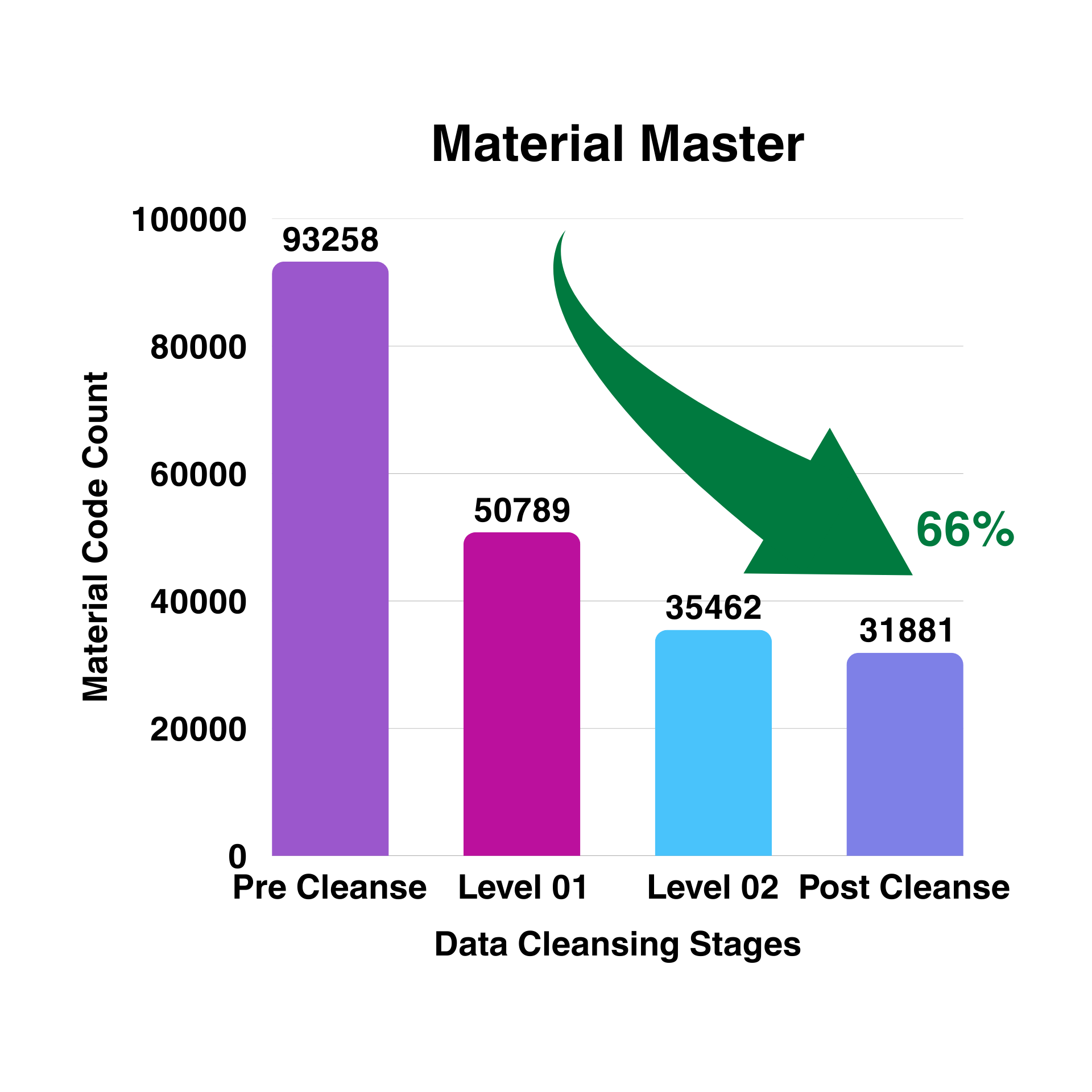

66% reduction in material codes i.e. 93,258 SKU’s reduced to 31,881 SKU’s

-

100% accuracy achieved for Data Standardization

-

85% accuracy achieved for Data Enrichment & Data Validation

2. Inventory Optimization Impact :

-

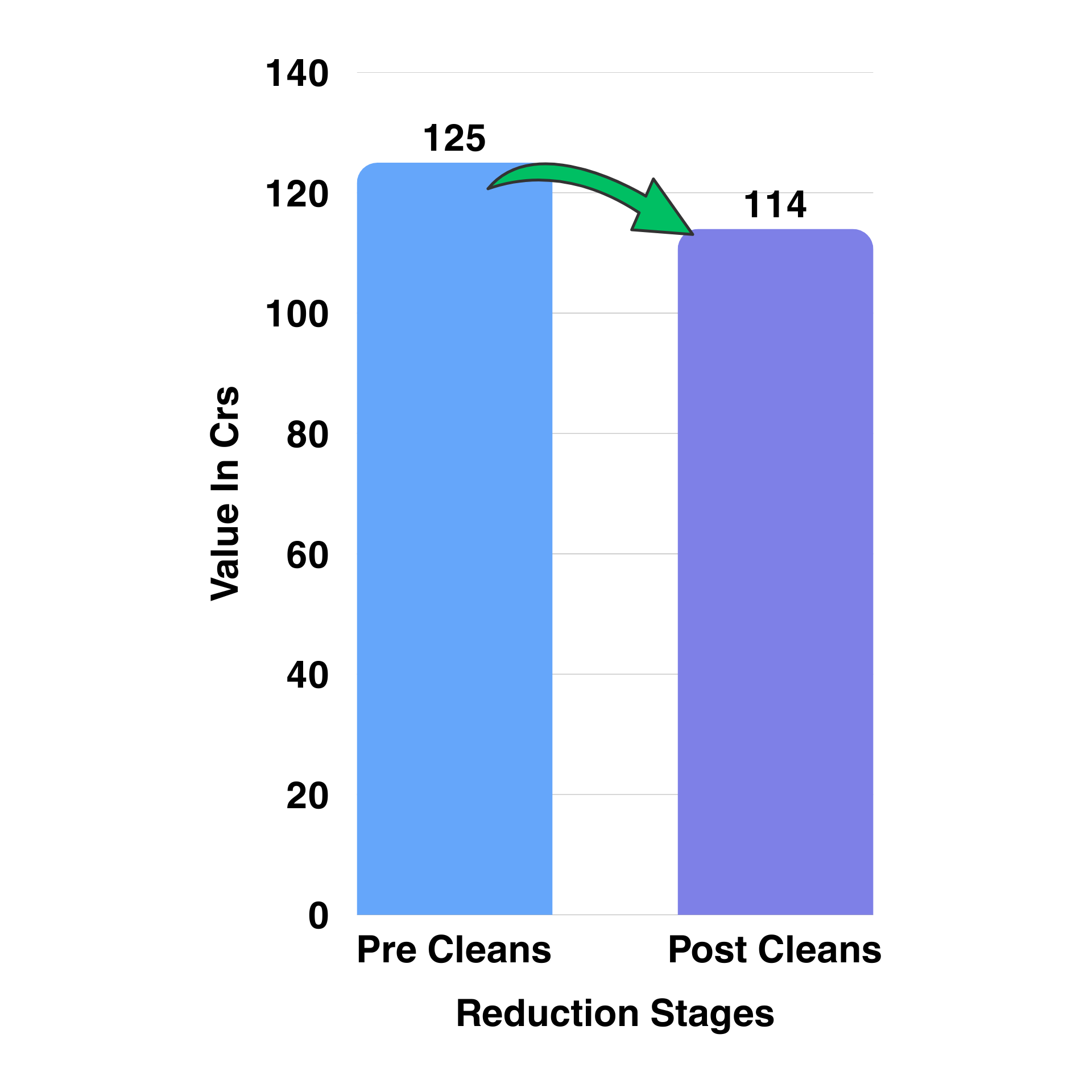

Inventory volume reduced from 125cr to 114cr (approx. 9% reduction) through cleansing insights

3. Data Sustainability Gains :

-

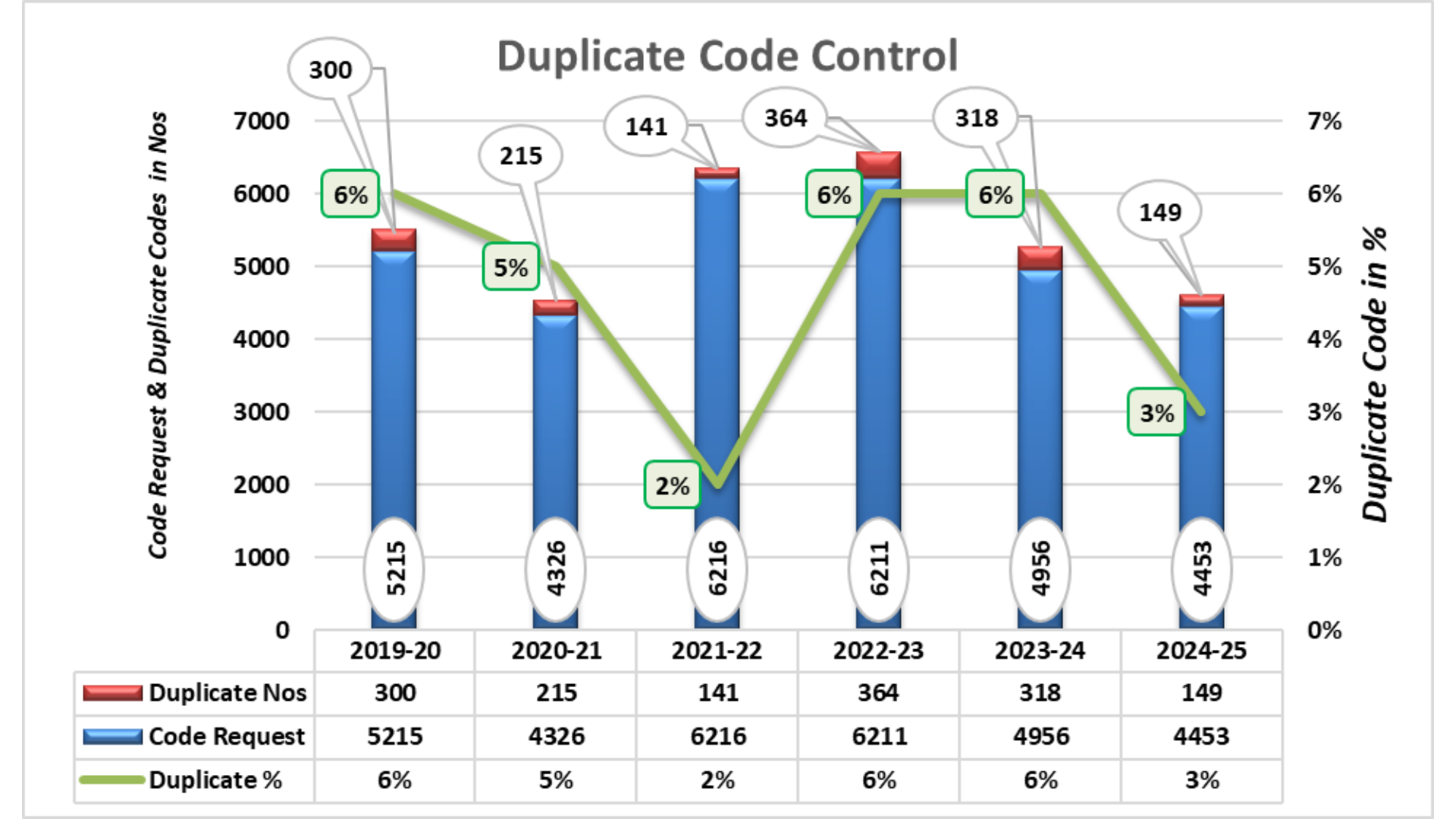

Governance controls enabled for new material code creation

-

Continuous duplicate prevention workflows implemented

-

YOY feedback loop established for ongoing accuracy monitoring

-

Long-term master data reliability secured across the organization

Key Outcomes Delivered :

-

Centralized Master Data Governance Model

-

Accurate and structured Material Master Database

-

Compliance-aligned OEM, MPN, HSN, and attribute, categories & group mapping

-

Duplicate-free code creation control

-

Reduced inventory waste and carrying cost

-

Sustainable data processes for future scalability

Conclusion

By implementing W2W’s Material Master Data Cleansing and Governance Platform, the client successfully transformed its master data into a single source of truth, enabling higher accuracy, compliance, inventory optimization, and long-term operational reliability.

This initiative now supports improved decision-making across procurement, supply chain, finance, and plant operations—creating a scalable model for continuous Master Data Quality Upliftment.